Locates shoes on the backing plate – In the realm of shoemaking and repair, the precise placement of shoes on the backing plate is a crucial step that ensures durability, comfort, and aesthetic appeal. This guide delves into the intricacies of locating shoes on the backing plate, providing a comprehensive overview of the process, materials, equipment, techniques, and quality control measures involved.

From understanding the different types of backing plates and the materials used to locate shoes, to mastering the techniques for precise alignment and achieving optimal results, this guide empowers you with the knowledge and skills necessary to execute this essential task with confidence.

Locate Shoes on Backing Plate: Locates Shoes On The Backing Plate

Accurately positioning shoes on a backing plate is crucial for successful shoemaking. Here’s a step-by-step guide to ensure precise placement:

Positioning the Heel

- Place the shoe on the backing plate, aligning the heel counter with the edge of the plate.

- Secure the heel with a clamp or tacks to prevent it from shifting.

Positioning the Forepart

- Mark the center point of the forepart on the backing plate.

- Align the shoe’s center point with the marked point on the plate.

- Secure the forepart with clamps or tacks, ensuring it is parallel to the heel.

- Check the overall fit of the shoe on the backing plate.

- Make any necessary adjustments to the heel or forepart positioning to ensure a snug and secure fit.

- Once satisfied with the fit, secure the shoe firmly to the backing plate with additional clamps or tacks.

- Steel:Steel is a strong and durable material that is often used for locating shoes in high-precision applications. It is resistant to wear and tear and can withstand high loads.

- Aluminum:Aluminum is a lightweight and corrosion-resistant material that is often used in applications where weight is a concern. It is not as strong as steel, but it is more affordable.

- Brass:Brass is a corrosion-resistant material that is often used in marine applications. It is more expensive than steel or aluminum, but it is more resistant to saltwater corrosion.

- Nylon:Nylon is a strong and durable plastic that is often used for locating shoes in low-precision applications. It is lightweight and inexpensive, but it is not as strong as steel or aluminum.

- Polyethylene:Polyethylene is a lightweight and flexible plastic that is often used for locating shoes in applications where flexibility is important. It is not as strong as nylon, but it is more resistant to chemicals.

- Polypropylene:Polypropylene is a strong and durable plastic that is often used for locating shoes in applications where high strength is required. It is more expensive than nylon or polyethylene, but it is more resistant to wear and tear.

- Description:A precision-machined device that holds the shoes in place and guides their placement on the backing plate.

- Function:Ensures accurate alignment and spacing of the shoes, preventing errors during assembly.

- Description:A precision measuring instrument that measures minute displacements and variations in position.

- Function:Used to verify the exact position of the shoes relative to the backing plate, ensuring they are perfectly aligned.

- Description:A flexible, calibrated tape measure used for accurate distance measurements.

- Function:Measures the distance between the shoes and the backing plate, ensuring proper spacing and alignment.

- Description:A precision tool used for drawing and checking right angles and straight lines.

- Function:Ensures that the shoes are perpendicular to the backing plate and aligned correctly.

- Description:A pointed tool used to mark the exact center of a hole or other location.

- Function:Creates a small indentation on the backing plate to guide the drilling of holes for shoe mounting.

- Description:A hand-held tool used for driving nails or other fasteners.

- Function:Used to secure the shoes to the backing plate after they have been accurately positioned.

- Simple and inexpensive |

- Requires a hole to be drilled in the shoe |

- Easy to use |

- Can be difficult to remove |

- Very precise |

- Can be bulky and expensive |

- Use a reference point or datum surface to align the shoes with the workpiece.

- Ensure that the shoes are parallel to each other and perpendicular to the workpiece.

- Use a square or straightedge to check the alignment of the shoes.

- Use a precision measuring instrument, such as a micrometer or dial indicator, to measure the distance between the shoes.

- Take multiple measurements to ensure accuracy.

- Record the measurements and compare them to the specified tolerances.

- Automotive Industry:Locating shoes are used to position engine components, such as pistons and bearings, with high accuracy.

- Aerospace Engineering:In aircraft manufacturing, locating shoes ensure the precise alignment of wings, engines, and other critical components.

- Machinery Manufacturing:Locating shoes help align shafts, gears, and other rotating components in heavy machinery.

- Construction:To align and position structural components, such as beams and columns.

- Medical Equipment:To precisely position imaging equipment, surgical tools, and patient beds.

- Electronics Assembly:To ensure accurate placement of components on circuit boards.

Adjusting the Fit

Types of Backing Plates

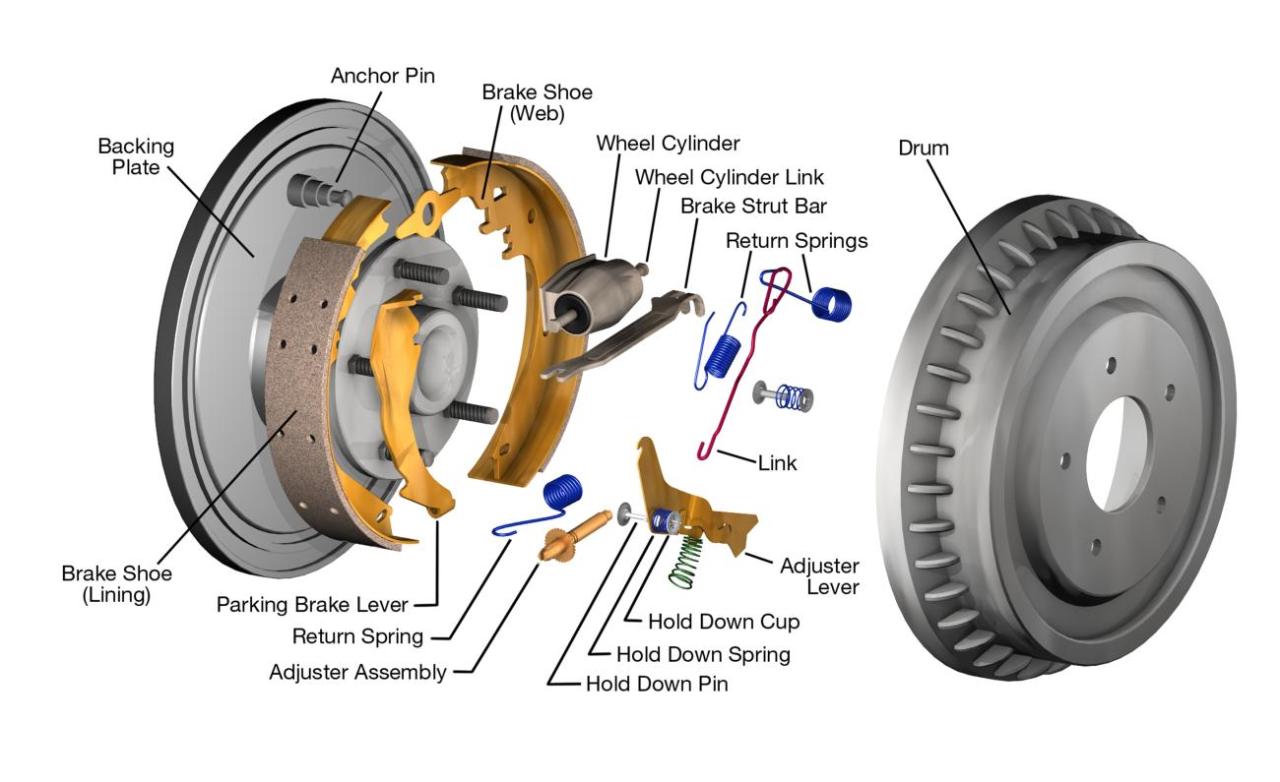

Backing plates are essential components of disc brakes, providing a solid foundation for the brake pads and ensuring efficient braking performance. They come in various types, each with its unique materials and construction, influencing the overall performance and durability of the brake system.

The most common types of backing plates include:

Steel Backing Plates

Steel backing plates are the most widely used type, offering a robust and cost-effective solution. They are typically made from high-strength steel, providing excellent durability and heat resistance. Steel backing plates are known for their ability to withstand high temperatures and pressures, making them suitable for demanding applications.

Aluminum Backing Plates

Aluminum backing plates are lightweight and corrosion-resistant, making them a popular choice for high-performance vehicles. They offer good heat dissipation, reducing the risk of brake fade during intense braking. However, aluminum backing plates may not be as durable as steel backing plates and can be more expensive.

Composite Backing Plates, Locates shoes on the backing plate

Composite backing plates combine the advantages of both steel and aluminum. They feature a steel core for strength and durability, with an aluminum surface for weight reduction and corrosion resistance. Composite backing plates offer a balance of performance and cost, making them suitable for a wide range of applications.

Ceramic Backing Plates

Ceramic backing plates are the most expensive type, but they offer exceptional heat resistance and durability. They are made from a ceramic material that can withstand extremely high temperatures, reducing the risk of brake fade and improving braking performance in demanding conditions.

Materials for Locating Shoes

When selecting materials for locating shoes on the backing plate, several factors must be considered, including the required accuracy, durability, and cost. The most commonly used materials include:

Metals

Plastics

Equipment for Locating Shoes

Locating shoes on a backing plate requires specialized equipment to ensure accuracy and efficiency. These tools are essential for achieving precise placement and alignment of the shoes during the manufacturing process.

The essential equipment for locating shoes on a backing plate includes:

Shoe Locating Fixture

Dial Indicator

Precision Measuring Tape

T-Square or Combination Square

Center Punch

Hammer

Techniques for Locating Shoes

There are several techniques used for locating shoes on the backing plate, each with its own advantages and limitations.

The most common technique is to use a locating pin. A locating pin is a cylindrical metal pin that is inserted into a hole in the shoe and the backing plate. The locating pin ensures that the shoe is positioned in the correct location on the backing plate.

Another technique is to use a locating ring. A locating ring is a metal ring that is placed around the shoe. The locating ring ensures that the shoe is positioned in the correct location on the backing plate and prevents the shoe from moving.

A third technique is to use a locating block. A locating block is a metal block that is placed against the shoe. The locating block ensures that the shoe is positioned in the correct location on the backing plate and prevents the shoe from moving.

Advantages and Limitations of Each Technique

The following table summarizes the advantages and limitations of each technique:

| Technique | Advantages | Limitations ||—|—|—|| Locating pin |

| Locating ring |

| Locating block |

Alignment and Precision

Alignment and precision are crucial when locating shoes on the backing plate. Proper alignment ensures that the shoes are correctly positioned relative to each other and to the workpiece. Precision ensures that the shoes are located accurately within the specified tolerances.

To achieve accurate and consistent results, the following tips should be followed:

Positioning

Measurement

Quality Control

Quality control measures are essential to ensure the accuracy and durability of locating shoes on the backing plate. These measures involve meticulous verification processes to guarantee the precision of the placement.

Inspection and Verification

Thorough inspections are conducted to verify the proper alignment and secure fit of the shoes on the backing plate. Inspectors utilize measuring tools, such as calipers and micrometers, to ensure the shoes meet the specified dimensions and tolerances. The durability of the placement is assessed through rigorous testing, including stress tests and vibration analysis, to ensure the shoes can withstand the demands of the application.

Applications

Locating shoes on the backing plate is a crucial process in various industries, enabling the precise positioning of components and ensuring optimal performance.

Industrial Applications

Other Applications

Beyond industrial settings, locating shoes also find applications in:

Top FAQs

What are the different types of backing plates?

Backing plates come in various materials, including steel, aluminum, and composite materials. Each material offers unique properties in terms of durability, weight, and cost.

What are the key considerations when choosing materials for locating shoes?

Factors to consider include the type of shoe, the desired level of durability, and the compatibility with the backing plate material.

What techniques are commonly used for locating shoes on the backing plate?

Techniques include manual alignment, laser alignment, and computer-aided alignment, each offering varying levels of precision and efficiency.